Blog

What is 3D Printing ? An Overview

What is 3D Printing ? An Overview

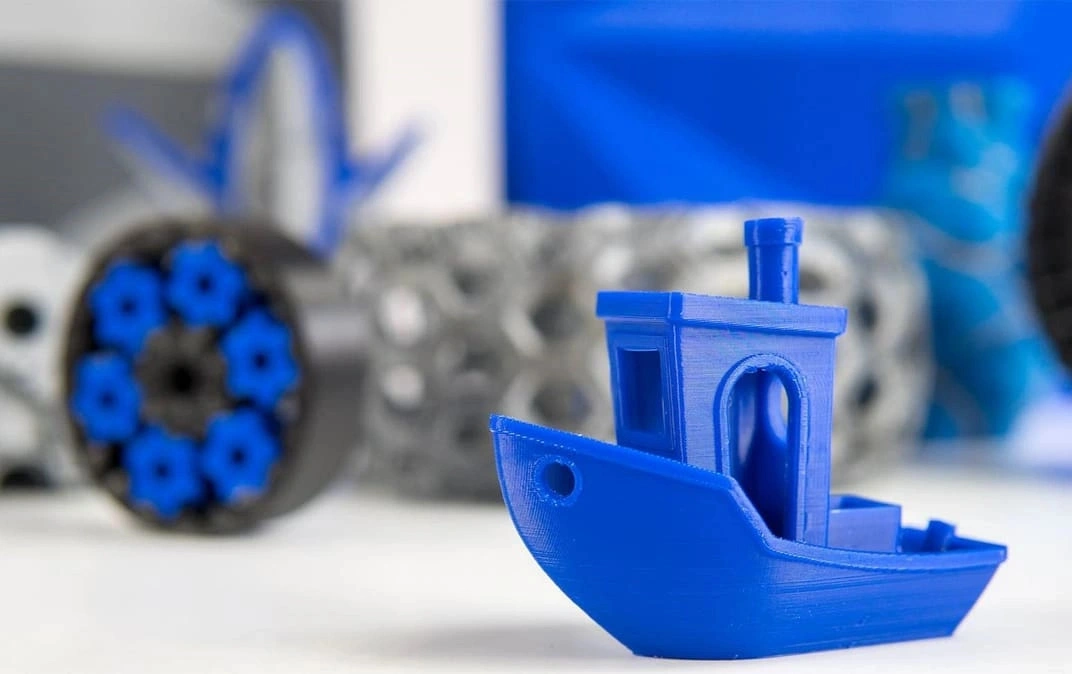

Have you ever imagined a world where you can transform digital designs into tangible objects with the press of a button? This isn’t science fiction; this is the revolutionary realm of 3D printing. In this guide, we’ll answer the fundamental question: what is 3D printing? More formally known as additive manufacturing, this technology is rapidly shifting paradigms across industries, from healthcare to aerospace. It’s a foundational technology poised to redefine how we design, produce, and interact with the physical world.

What is 3D Printing, Really? Understanding the Core Concept

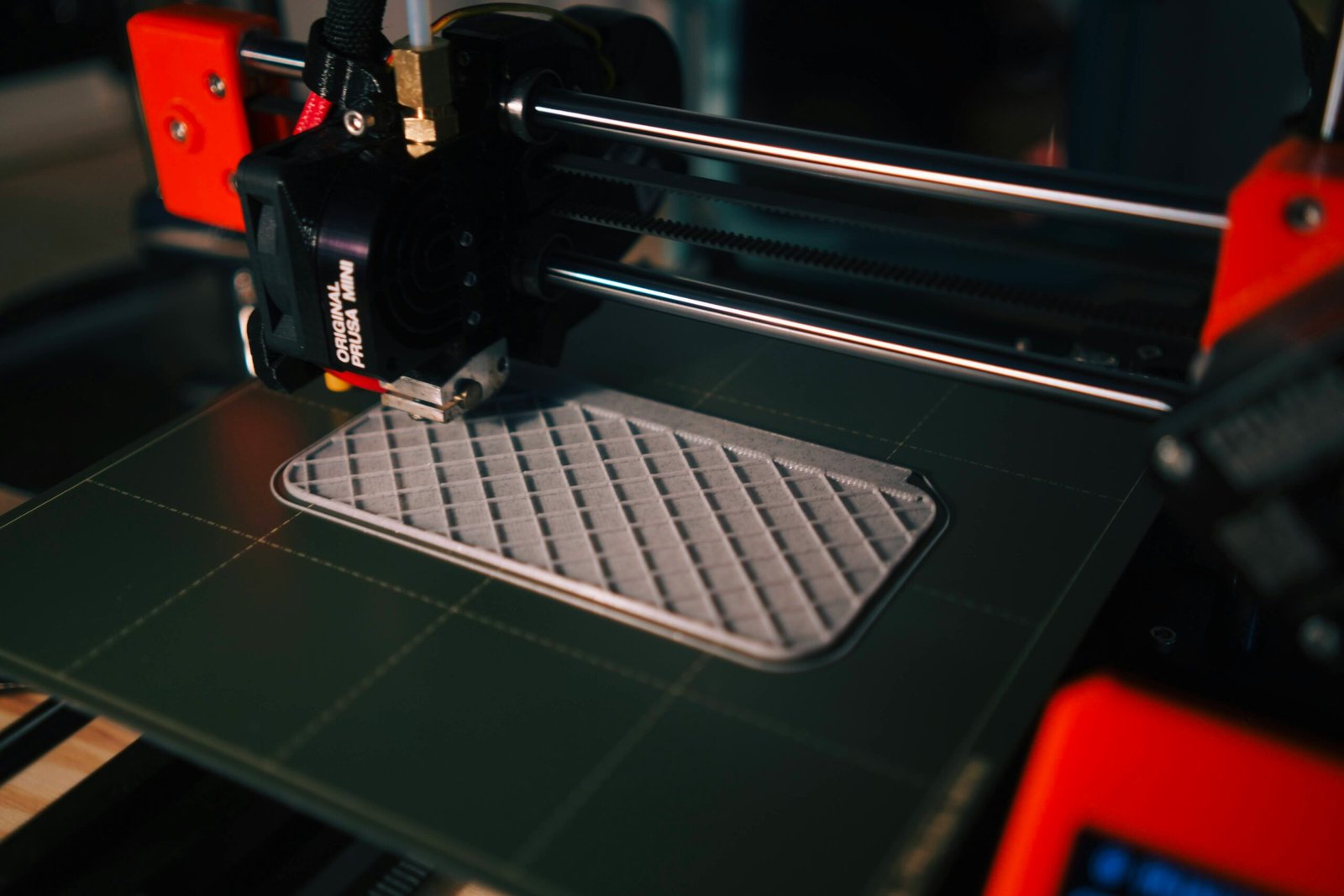

At its heart, 3D printing is an additive manufacturing process. Unlike traditional “subtractive” methods (think carving or drilling, which remove material from a larger block), 3D printing builds objects layer by painstaking layer from the ground up. It starts with a digital 3D model and then, under computer control, deposits or solidifies material precisely where needed until the object is complete.

Imagine stacking countless ultra-thin slices of an object on top of each other – that’s essentially what a 3D printer does. This fundamental difference unlocks a world of design freedom and efficiency that was previously unimaginable. It allows for the creation of complex shapes and internal structures that are impossible to produce with traditional methods.

A Brief History: The Evolution of 3D Printing Technology

While it might seem like a recent innovation, the concept of 3D printing has roots stretching back to the 1980s. Chuck Hull, co-founder of 3D Systems, is widely credited with inventing stereolithography (SLA) in 1984, paving the way for commercializing this groundbreaking technology. For decades, it was primarily used for rapid prototyping, allowing engineers and designers to quickly test iterations of their designs.

However, as explained by industry leaders at Formlabs, advancements in materials science, software, and hardware have dramatically lowered costs and increased capabilities. Today, 3D printing has moved beyond mere prototyping to become a viable method for producing functional end-use parts. (Looking for your first machine? Check out our guide on [the best 3D printers for beginners].)

How Does it Work? The 3D Printing Process Explained

The 3D printing process can be broken down into a few key stages:

- 3D Model Creation: This is the blueprint. Designers use Computer-Aided Design (CAD) software (like SolidWorks, Fusion 360, or Blender) to create a digital 3D model. Alternatively, an object can be 3D scanned to create a digital replica.

- Slicing Software: The 3D model is loaded into “slicing” software. This program digitally dissects the model into hundreds of horizontal layers and generates a set of instructions (G-code) for the printer.

- Material Selection: The choice of material is crucial. Common materials include plastics (PLA, ABS), resins, and even metals like titanium and aluminum. (Learn more about [choosing the right 3D printing material for your project].)

- Printing: The 3D printer executes the instructions, building the object layer by layer. The specific method depends on the type of 3D printer.

- Post-Processing: Once complete, the object may require finishing touches like removing support structures, sanding, or curing.

(To see this in action, watch a time-lapse video of a 3D print. A great example can often be found on platforms like YouTube, showing the fascinating layer-by-layer process.)

Exploring Different 3D Printing Technologies

There isn’t just one type of 3D printing. It’s a family of technologies, each with unique advantages. Some of the most common include:

- FDM (Fused Deposition Modeling): The most popular and affordable method. It works by extruding a thermoplastic filament through a heated nozzle.

- SLA (Stereolithography): Uses a UV laser to cure liquid photopolymer resin. Known for high detail and smooth finishes.

- SLS (Selective Laser Sintering): Employs a high-power laser to fuse powdered material into a solid structure, producing strong, functional parts.

For a deeper dive into these and other methods, educational resources like the Additive Manufacturing page at MIT provide excellent, in-depth information.

The Real-World Impact of 3D Printing

So, beyond the technical details, what is 3D printing actually used for? The implications are vast and continue to expand:

- Rapid Prototyping & Product Development: Significantly reduces time and cost in bringing new products to market.

- Customization & Personalization: Enables the creation of bespoke items, from medical implants and prosthetics to custom-fit consumer goods.

- On-Demand Manufacturing: Reduces the need for large inventories and allows for production closer to the point of consumption.

- Complex Geometries: Unlocks the ability to create intricate designs impossible with traditional manufacturing.

- Sustainable Practices: Can reduce material waste and enable the repair of parts instead of full replacement.

The Future is Now: Embracing Additive Manufacturing

3D printing is no longer just a futuristic concept; it’s a powerful, accessible technology that’s revolutionizing industries. From creating life-saving medical devices to crafting custom jewelry, and even building houses, its potential is truly limitless. As materials and technologies continue to evolve, 3D printing will undoubtedly play an even more central role in shaping our designed and built environment.

Now that you can confidently answer the question “What is 3D printing?”, are you ready to explore the possibilities it holds? The future of manufacturing is here, and it’s additive!