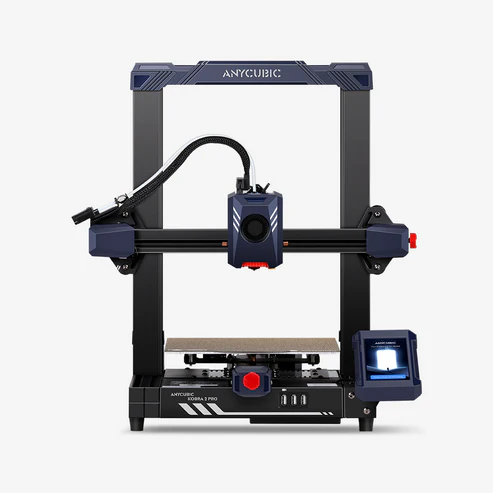

Introduction to the Anycubic Kobra 2 Pro

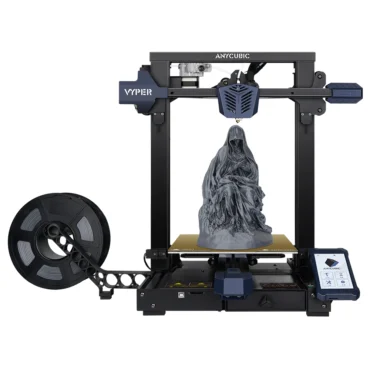

The Anycubic Kobra 2 Pro 3D printer offers exceptional printing capabilities and innovative features. Designed for both beginners and seasoned users, this printer delivers high-quality results with impressive precision.

Key Features

Equipped with a large build volume and an intuitive user interface, the Anycubic Kobra 2 Pro ensures a smooth printing experience. Its reliable extrusion system and advanced technology streamline filament loading and calibration processes.

Why Choose the Anycubic Kobra 2 Pro?

The Anycubic Kobra 2 Pro 3D printer stands out for its robustness and versatility, making it ideal for a variety of projects. Whether you’re working on prototypes or creative designs, this printer caters to all your needs, providing excellent value for your investment.

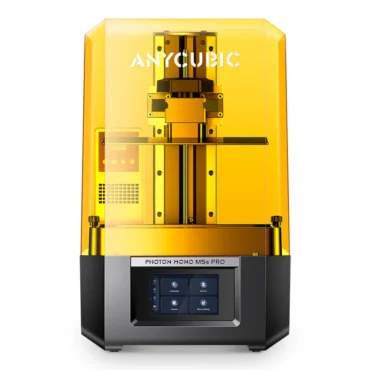

Anycubic Photon Mono M7 Pro

eSUN PETG Filament

Anycubic Kobra 3 Combo

eSUN PLA-LW Filament

Reviews

There are no reviews yet.