Blog

How 3D Printing Compares to CNC Machining :The Definitive Guide

How 3D Printing Compares to CNC Machining: A Complete Guide for Beginners

Introduction: Two Technologies Shaping Modern Manufacturing

If you’ve ever wondered how prototypes, custom parts, or even high-end aerospace components are made, chances are they came from either 3D printing or CNC machining. Both are powerful manufacturing methods, yet they operate in fundamentally different ways — one builds objects layer by layer, while the other carves them from solid blocks.

Understanding the strengths, weaknesses, and applications of each is essential, whether you’re an engineer, entrepreneur, or simply curious about modern manufacturing. In this guide, we’ll break down how each process works, where they shine, and how to choose between them — all without assuming you have a background in engineering.

1. The Basics: How Each Method Works ,3D Printing Compares to CNC Machining

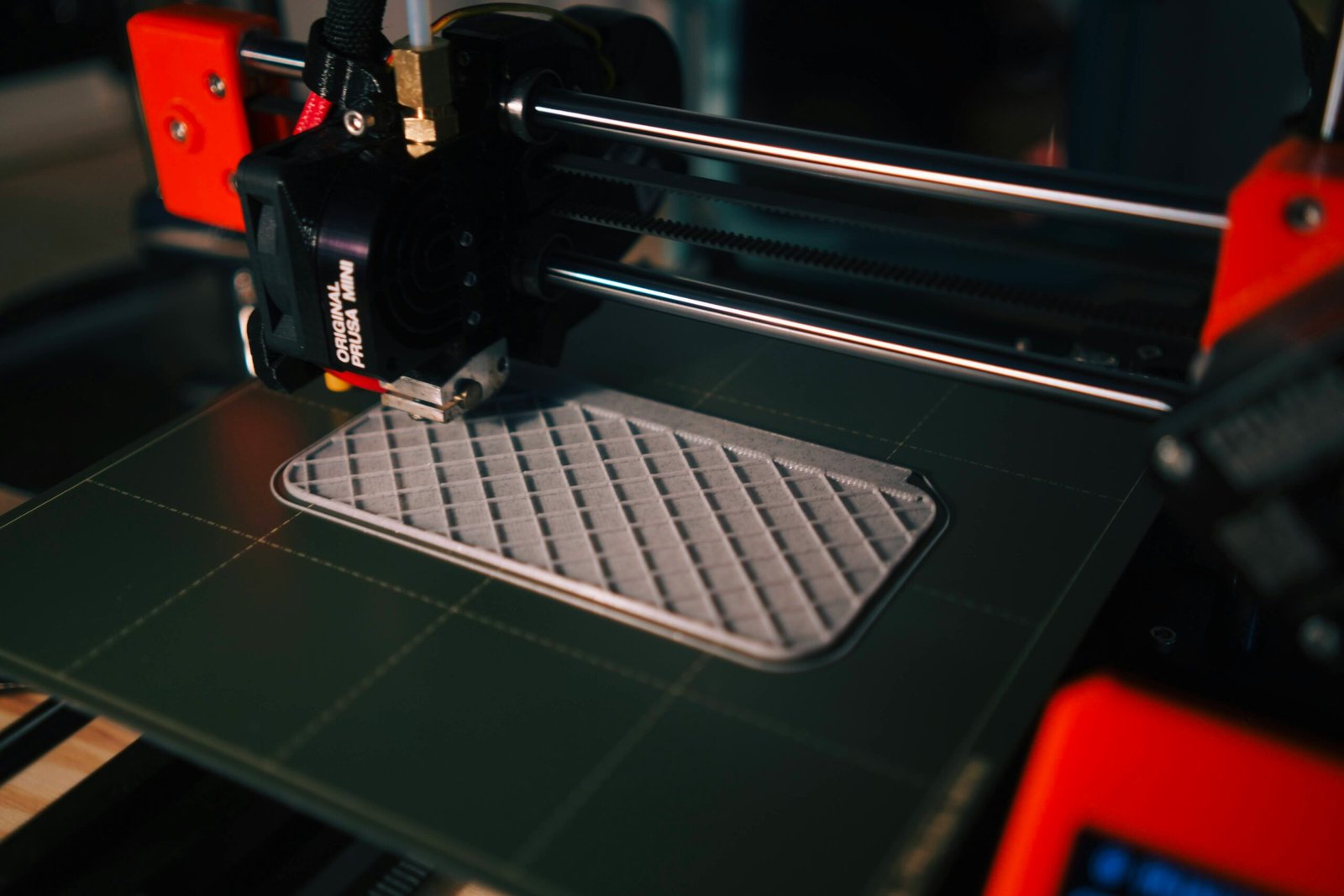

1.1 What Is 3D Printing?

3D printing, also called additive manufacturing, creates objects by adding material layer by layer. Imagine building a model from thin slices of material until it forms a complete 3D shape. The printer follows a digital 3D model, usually in STL or OBJ format.

Example: Printing a phone case involves laying down thin layers of plastic filament (like PLA or ABS) until the entire case is complete.

Common 3D Printing Technologies:

- FDM (Fused Deposition Modeling): Uses melted thermoplastic filament. Affordable and widely used.

- SLA (Stereolithography): Uses liquid resin cured by UV light. Offers high detail.

- SLS (Selective Laser Sintering): Uses powdered material fused by a laser. Great for complex, strong parts.

3D Printing Compares to CNC Machining

1.2 What Is CNC Machining?

CNC machining (Computer Numerical Control) is a subtractive manufacturing process. Instead of adding material, it starts with a solid block (metal, plastic, wood, etc.) and removes excess material using cutting tools, drills, and mills.

Example: Machining a gear involves carving away sections of a metal block until only the gear shape remains.

Common CNC Machines:

- CNC Mills: Cut along multiple axes for complex shapes.

- CNC Lathes: Spin material while shaping it with stationary tools.

- CNC Routers: Great for large sheets of wood or plastic.

2. Additive vs. Subtractive: The Core Difference

Think of 3D printing as drawing with a pen until the picture is complete, and CNC machining as carving a sculpture from a block of stone.

- 3D Printing: Builds up material only where needed.

- CNC Machining: Removes material until the desired shape is achieved.

This difference affects cost, speed, material waste, and design possibilities.

3. Materials: What Can They Work With? 3D Printing Compares to CNC Machining

3.1 3D Printing Materials

- Plastics: PLA, ABS, PETG, Nylon.

- Resins: Standard, flexible, high-temperature.

- Metals: Stainless steel, titanium, aluminum (via metal printing methods).

- Others: Composites with carbon fiber, wood-filled filaments.

Limitations: While 3D printing can handle metals, it often requires expensive industrial equipment. Most desktop 3D printers focus on plastics and resins.

3.2 CNC Machining Materials

- Metals: Aluminum, brass, steel, titanium.

- Plastics: PEEK, acrylic, Delrin.

- Wood: Hardwood, MDF, plywood.

Advantages: CNC can work with a much wider range of metals and harder materials without requiring specialized setups.

4. Precision and Surface Finish

4.1 3D Printing Accuracy

- Typical resolution: ±0.1–0.2 mm (can be better with high-end machines).

- Surface often shows visible layer lines that may require sanding or polishing.

4.2 CNC Machining Accuracy

- Typical tolerance: ±0.01 mm — much more precise than most 3D printers.

- Produces smooth surfaces directly from the machine, often with no post-processing needed.

Analogy: 3D printing is like stacking thin slices of bread to make a loaf, while CNC is like slicing a loaf perfectly from a solid piece of dough — smoother and more exact.

5. Complexity of Designs : 3D Printing Compares to CNC Machining

5.1 3D Printing’s Geometric Freedom

3D printing can produce internal cavities, lattice structures, and complex shapes that would be impossible to cut from a solid block. This makes it ideal for:

- Lightweight aerospace parts

- Medical implants tailored to a patient’s anatomy

- Custom artistic sculptures

Case Study: Airbus uses 3D-printed titanium brackets in aircraft to reduce weight while maintaining strength.

5.2 CNC Machining’s Design Constraints

CNC tools must physically reach the surfaces they cut. This limits certain shapes, especially internal voids. Complex designs may require multiple setups or specialized tooling.

However, CNC can handle designs that need tight tolerances and perfectly flat surfaces, such as engine components or precision molds.

6. Speed and Production Scale

6.1 3D Printing Speed

- Prototyping: Excellent — parts can be printed overnight without human supervision.

- Mass Production: Slower for large volumes; each part takes time to print individually.

6.2 CNC Machining Speed

- Prototyping: Slower to set up, but once programmed, machining can be fast.

- Mass Production: Very efficient — CNC machines can run continuously and produce hundreds of identical parts.

Example: If you need one custom drone frame, 3D printing may be faster. If you need 500 identical frames, CNC will likely win.

7. Cost Considerations

7.1 3D Printing Costs

- Machine Price: Entry-level printers start under $300; industrial models cost thousands.

- Material Cost: Relatively low for plastics, higher for metal powders.

- Setup Cost: Minimal — just load the model and print.

7.2 CNC Machining Costs

- Machine Price: Industrial CNC machines can cost tens of thousands of dollars.

- Material Cost: Depends on stock material; metals are more expensive.

- Setup Cost: Higher due to programming and tooling.

General Rule: 3D printing is cheaper for small quantities and complex designs; CNC is cheaper for large runs of simple parts.

8. Environmental Impact

- 3D Printing: Generates less waste because material is only added where needed. However, plastic filaments may not be recyclable.

- CNC Machining: Produces more scrap material, but metal waste is often recyclable.

9. Which Should You Choose?

How 3D Printing Compares to CNC Machining: A Complete Guide for Beginners

| Factor | 3D Printing | CNC Machining |

|---|---|---|

| Design Complexity | Excellent for complex shapes | Limited by tool access |

| Precision | Good (±0.1 mm) | Excellent (±0.01 mm) |

| Material Range | Mostly plastics/resins | Wide (metals, plastics, wood) |

| Setup Time | Minimal | Higher setup time |

| Cost for Small Runs | Lower | Higher |

| Mass Production | Slower | Faster |

| Surface Finish | May require post-processing | Smooth, ready-to-use |

Conclusion: The Future of Manufacturing is Hybrid

3D printing and CNC machining are not rivals so much as complementary tools in the modern manufacturing toolbox.

- If you need rapid prototyping, intricate designs, or low-volume custom parts, 3D printing is often the better choice.

- If you need high precision, a wide range of materials, or large-scale production, CNC machining usually wins.

In many industries, companies now combine both — 3D printing to create prototypes or complex inserts, and CNC machining to finish them to exact tolerances.

As technology advances, the lines between these methods will blur even further. Hybrid machines that can both print and machine are already in development, promising a future where manufacturers can switch seamlessly between additive and subtractive processes.