Blog

How 3D Printers Work : The Basics Explained

How 3D Printers Work: The Basics Explained

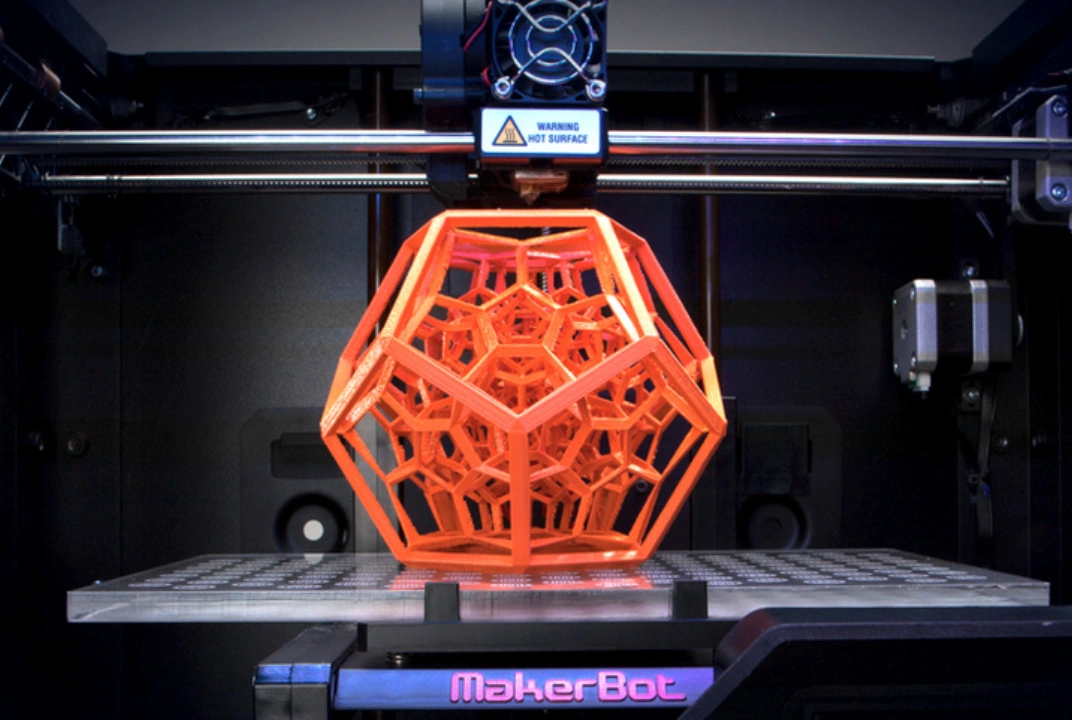

Have you ever imagined holding a custom-designed object that, just hours before, only existed as a file on your computer? That’s the incredible reality of 3D printing. Understanding how 3D printers work can seem complex, but it boils down to a single, elegant concept: additive manufacturing.

Instead of carving a shape from a solid block (subtractive manufacturing), a 3D printer builds an object from the ground up. It adds material one microscopic layer at a time, fusing each new layer to the one below it until the final object is complete. It’s a revolutionary process that turns digital blueprints into tangible reality.

How 3D Printers Work: The 3-Stage Process

At its heart, the way 3D printers work can be broken down into three simple stages: designing the model, slicing it for the printer, and the final printing process.

Stage 1: Creating a Digital Design

Every print starts with a 3D model, which is the digital blueprint. You can get one in a few ways:

- Design it yourself: Using beginner-friendly software like Tinkercad or professional tools like Blender, you can create a model from scratch. If you’re new to the field, check out our guide on the [best 3D modeling software for beginners].

- Download a pre-made model: The easiest way to get started is by downloading one of the millions of free models from online communities like Thingiverse or Printables.

- Scan a real-world object: A 3D scanner can digitally capture an existing object and turn it into a printable file.

This digital blueprint is typically saved as an STL (.stl) file, the standard format recognized by 3D printing software.

Stage 2: Slicing the Model into Instructions

A 3D printer doesn’t understand an STL file directly. It needs a detailed, step-by-step instruction manual. This is where slicing software comes in.

A “slicer,” like the popular free program Ultimaker Cura, is essential to how 3D printers work. It digitally cuts your 3D model into hundreds or thousands of thin horizontal layers. Then, it generates a file called G-code, which contains the exact coordinates and commands the printer will follow—from the nozzle’s path and print speed to the precise temperature.

Stage 3: The Printing Process Explained ️

This is where the magic happens. The printer reads the G-code and begins building. The most common technology for consumer printers is Fused Deposition Modeling (FDM). Understanding this method is key to understanding how most home 3D printers work.

- Loading Material: A spool of plastic material called filament is fed into the printer. (Learn more about [choosing the right 3D printer filament] in our complete guide).

- Melting and Extruding: The printer pulls the filament into a hot nozzle, called an extruder, which melts it into a semi-liquid state.

- Building Layer by Layer: The extruder moves along the X, Y, and Z axes, precisely drawing the first layer of molten plastic onto the build platform. Once a layer is complete, the platform moves down slightly, and the process repeats, fusing each new layer to the last until the object is fully formed.

A Closer Look at How Different 3D Printers Work

While FDM is extremely popular, other technologies offer different results. The fundamental layer-by-layer process is the same, but the materials and methods vary.

- Stereolithography (SLA): These printers use an ultraviolet (UV) laser to cure and solidify a liquid resin inside a tank. SLA is known for producing objects with incredibly fine detail and smooth surfaces.

- Selective Laser Sintering (SLS): An SLS printer uses a powerful laser to heat and fuse powdered material, such as nylon or metal, together. This method creates exceptionally strong and durable parts, making it common in industrial applications.

From rapid prototyping to custom gadgets, the process of how 3D printers work is transforming industries. By turning digital concepts into physical items, this technology puts the power of manufacturing into the hands of creators everywhere.