Blog

Different Types of 3D Printing Technologies

Different Types of 3D Printing Technologies : An Ultimate Guide (2025)

Exploring the different types of 3D printing can feel overwhelming. You’ve seen the wild examples—everything from a simple plastic keychain to a flight-ready metal rocket engine. How can one technology do it all?

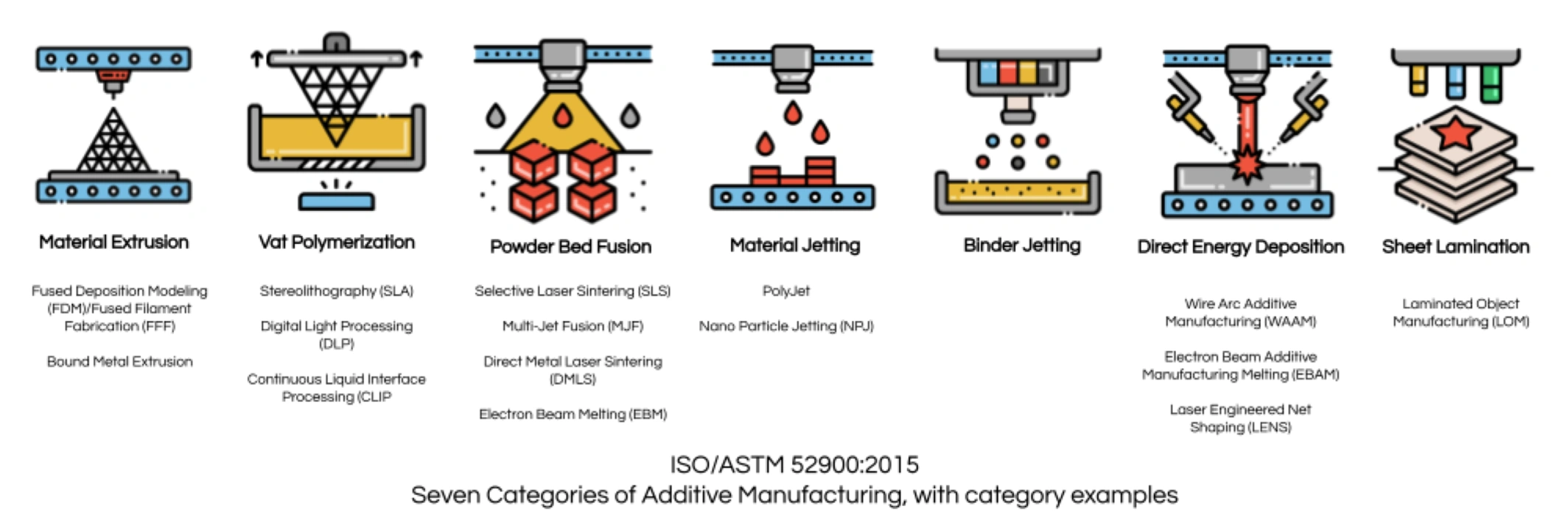

The secret is that “3D printing” isn’t one single technology. It’s a whole family of different processes, all falling under the umbrella of Additive Manufacturing (AM). The one thing they have in common? They all build objects layer-by-layer from a digital file.

But how they build those layers—and what materials they use—changes everything.

Understanding these differences is the key to unlocking the right technology for your project, budget, and quality needs. Let’s break down the 7 main types of 3D printing.

1. Material Extrusion (FDM): The Most Common & Affordable

This is the most common of all the types of 3D printing, and it’s what most people picture when they hear the term.

- Common Process: Fused Deposition Modeling (FDM)

- How it Works: Think of it as a smart, robotic hot glue gun. A spool of solid plastic (called filament) is pushed into a hot nozzle, where it melts. The printer moves this nozzle to draw the shape of each layer, which quickly cools and solidifies.

- Materials: Thermoplastics like PLA (easy to use, eco-friendly), ABS (strong, durable), and PETG (food-safe, tough).

- Pros:

- Most affordable and widely accessible.

- Huge variety of material colors and types.

- Simple, fast, and easy to maintain.

- Cons:

- Visible layer lines are common.

- Lowest resolution and detail compared to other methods.

- Parts are weaker along the layer lines (anisotropic).

- Best For: Hobbyists, rapid prototyping, educational tools, custom jigs, and simple functional parts.

2. Vat Polymerization (SLA/DLP): For Unbeatable Detail

This was the very first 3D printing technology, and it’s still the king of high-resolution models.

- Common Processes: Stereolithography (SLA) & Digital Light Processing (DLP)

- How it Works: Both methods start with a vat (tank) of liquid photopolymer resin. A UV light source selectively “cures” (hardens) the resin, forming a solid layer.

- SLA uses a single UV laser to precisely trace the layer’s pattern.

- DLP uses a digital projector (like a tiny movie projector) to flash an image of the entire layer at once, making it generally faster.

- Materials: Photopolymer resins (e.g., standard, tough, flexible, castable for jewelry, dental-grade).

- Pros:

- Extremely high resolution and fine detail.

- Produces a glass-smooth surface finish.

- Excellent for intricate and complex designs.

- Cons:

- Messy post-processing is required: parts must be washed in alcohol and cured under UV light to gain full strength.

- Parts can be brittle and are not ideal for outdoor use (UV sensitive).

- Resins are more expensive and messier than FDM filament.

- Best For: Jewelry (casting molds), dental models, detailed miniatures and figurines, high-fidelity visual prototypes.

3. Powder Bed Fusion (SLS & DMLS): For Strong, Functional Parts

This is a powerful, industrial technology that builds strong, complex parts from a bed of fine powder.

- Common Processes: Selective Laser Sintering (SLS) & Direct Metal Laser Sintering (DMLS)

- How it Works: A high-powered laser draws a pattern on a bed of fine powder, fusing the particles together. A new, thin layer of powder is spread over the top, and the process repeats.

- SLS sinters (heats without fully melting) polymer powders like nylon.

- DMLS/SLM (Selective Laser Melting) fully melts metal powders like titanium, aluminum, and stainless steel.

- Key Feature of SLS: The unused powder in the bed acts as its own support material. This means no support structures are needed, allowing for incredibly complex, interlocking, and moving parts to be printed in one go.

- Pros:

- Produces strong, functional end-use parts with great mechanical properties.

- SLS allows for extreme design freedom (no supports).

- Wide range of industrial materials, including metals.

- Cons:

- Very expensive machinery and materials.

- Requires significant post-processing (de-powdering and, for metal, stress relief in a furnace).

- Best For: Functional prototypes, end-use parts for aerospace and automotive, medical implants (DMLS), complex ductwork.

Other Key Types of 3D Printing: 4-7

While FDM, SLA, and SLS are the “big three,” these other technologies are critical for specific, high-end applications.

4. Material Jetting (PolyJet)

- Analogy: A 2D inkjet printer, but it jets 3D material.

- How it Works: Printheads jet thousands of tiny droplets of photopolymer resin onto the build plate, which are instantly cured by a UV lamp. It can jet different materials and colors from different nozzles in the same pass.

- Best For: Creating stunningly realistic, multi-color, and multi-material prototypes (e.g., a model with hard plastic, flexible rubbery sections, and clear parts, all printed as one piece).

5. Binder Jetting

- Analogy: Gluing powder together, layer by layer.

- How it Works: A printhead sprays a liquid binding agent (glue) onto a bed of powder (like sand, metal, or gypsum). This is one of the few methods that doesn’t use heat.

- Best For: Creating large-scale sand casting molds for foundries, or full-color (but brittle) models for architectural mockups and art.

6. Directed Energy Deposition (DED)

- Analogy: A high-tech, robotic welder.

- How it Works: A nozzle melts metal powder or wire as it’s being deposited. DED is often used to add material to existing parts for repair or modification, rather than just building from scratch.

- Best For: Repairing large, high-value metal components (like turbine blades), large-scale structural parts.

7. Sheet Lamination

- Analogy: Building a model from a stack of precisely cut paper.

- How it Works: It builds objects by stacking and laminating thin sheets of material (like paper, plastic, or metal foil) that are cut with a laser or blade.

- Best For: Inexpensive visual prototypes, and in some cases, creating composite or metal objects.

How to Choose Between Different Types of 3D Printing Technologies

Don’t ask, “What’s the best of all the types of 3D printing?” Instead, ask, “What’s the best technology for my project?”

Are you prioritizing cost, speed, strength, or detail? This chart will help you decide.

| Technology | Common Process | Primary Benefit | Common Use Case |

|---|---|---|---|

| Material Extrusion | FDM | Affordability & Ease of Use | Hobbyists, Prototyping |

| Vat Polymerization | SLA / DLP | High Detail & Smooth Finish | Jewelry, Dental, Miniatures |

| Powder Bed Fusion | SLS | Strong Parts, No Supports | Functional End-Use Parts |

| Powder Bed Fusion | DMLS/SLM | Strong, Dense Metal Parts | Aerospace, Medical Implants |

| Material Jetting | PolyJet | Full-Color & Multi-Material | Realistic Visual Prototypes |

| Binder Jetting | BJ | Large Scale & Low-Cost Metal | Sand Casting, Full-Color Figures |

| Directed Energy | DED | Repairing & Adding Metal | Industrial Repair, Large Parts |

The Future is Layered

As you can see, “3D printing” is not a single machine—it’s a diverse toolbox. The technology you choose will completely change your final part’s look, feel, and strength.

The field is evolving at lightning speed, with new materials and faster processes making additive manufacturing a serious competitor to traditional methods. From a hobbyist’s garage to a rocket factory, there’s a 3D printing technology designed for the job.

What’s the most amazing thing you’ve seen 3D printed? Let us know in the comments below!