Blog

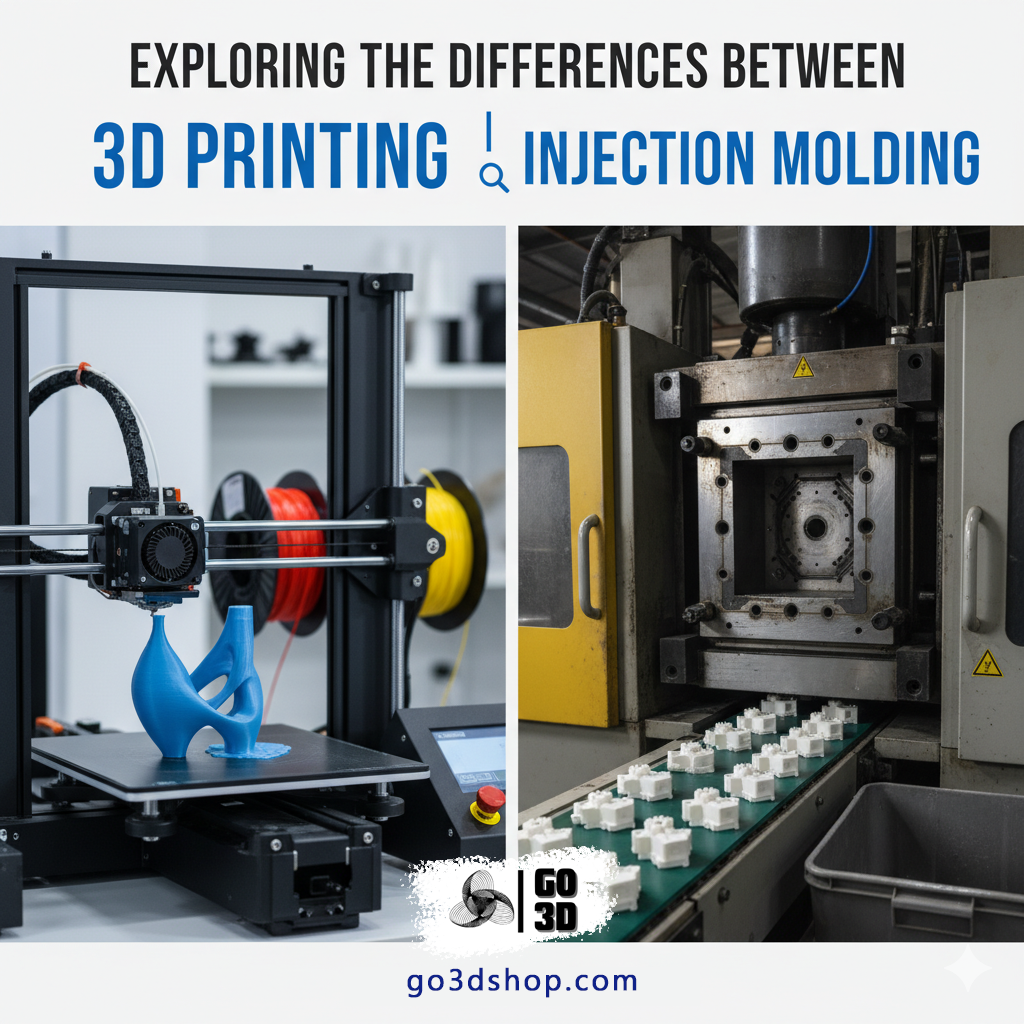

The Ultimate Showdown : Exploring the Differences Between 3D Printing and Injection Molding

Exploring the Differences Between 3D Printing and Injection Molding

Introduction: Two Manufacturing Titans

3D Printing and Injection Molding

In the world of manufacturing, two processes often dominate conversations — 3D printing and injection molding. Both methods can transform raw materials into functional products, yet they differ dramatically in technology, speed, cost, and applications.

If you’ve ever wondered why a company might choose to 3D print a prototype but mass-produce the final product using injection molding, you’re not alone. These processes aren’t rivals as much as they are specialists in different scenarios, each excelling under certain conditions.

In this article, we’ll break down how each method works, compare their strengths and weaknesses, and explore how industries decide between them.

1. How the Processes Work

1.1 3D Printing: Building Layer by Layer

3D printing, also known as additive manufacturing, creates objects by depositing material layer upon layer until the final form is achieved.

-

Workflow:

-

A 3D model is designed in CAD software.

-

The model is sliced into thin layers by software.

-

A printer builds the object one layer at a time using materials like plastics, resins, or metals.

-

-

Popular Methods:

-

FDM (Fused Deposition Modeling) – melts plastic filament and extrudes it through a nozzle.

-

SLA (Stereolithography) – cures liquid resin with UV light.

-

SLS (Selective Laser Sintering) – fuses powdered material with a laser.

-

-

Analogy: Imagine building a house brick-by-brick, but each brick is just a tiny layer of your final product.

1.2 Injection Molding: Shaping in Seconds

Injection molding is a subtractive-molding process that shapes molten material inside a mold cavity under high pressure.

-

Workflow:

-

A mold (usually made from steel or aluminum) is manufactured with the desired shape.

-

Material (often thermoplastic pellets) is heated until molten.

-

The molten material is injected into the mold.

-

The part cools, solidifies, and is ejected from the mold.

-

-

Analogy: Think of filling an ice cube tray with water, freezing it, and popping out identical ice cubes — only faster, hotter, and with plastic instead of water.

2. Speed and Production Volume

2.1 3D Printing’s Pace

3D printing is generally slower than injection molding for a single part, but faster for prototypes or small batches because it requires no mold-making.

-

Printing a complex prototype might take a few hours to a day.

-

Perfect for rapid iteration where design changes are frequent.

2.2 Injection Molding’s Efficiency

Once the mold is ready, injection molding can produce parts in seconds or minutes per cycle.

-

Ideal for mass production — thousands or millions of identical parts.

-

Mold creation can take weeks and cost thousands of dollars, so it’s less suitable for one-off projects.

3. Cost Considerations

3.1 Upfront Costs

-

3D Printing: Low initial cost — no expensive molds, just the printer and material.

-

Injection Molding: High upfront investment — molds can cost from $5,000 to $100,000+ depending on complexity.

3.2 Cost per Part

-

3D Printing: Cost per part stays relatively constant regardless of quantity.

-

Injection Molding: Cost per part drops dramatically as volume increases, due to mold reusability.

Case Study:

A startup making 100 custom phone cases might choose 3D printing — at $5 per case, the total is $500. Injection molding could require a $10,000 mold plus $0.50 per case, totaling $10,050 — clearly not economical for small runs.

4. Design Flexibility

4.1 Complex Shapes with 3D Printing

3D printing excels at intricate, organic, or hollow designs that might be impossible with molding.

-

Internal channels, lattice structures, or one-piece moving parts are feasible.

-

Design changes are quick — just update the CAD file and print again.

4.2 Limitations in Injection Molding

Injection molding works best for geometrically simple parts without deep undercuts or extreme internal features. Complex designs may require multi-part molds, which increase cost and complexity.

5. Material Options and Properties

5.1 3D Printing Materials

-

Common: PLA, ABS, PETG, resin, nylon.

-

Specialty: Metal powders, carbon fiber-reinforced filaments, flexible TPU.

-

Properties vary — 3D printed parts can be weaker along layer lines.

5.2 Injection Molding Materials

-

Huge range: ABS, polycarbonate, polypropylene, polyethylene, and engineering-grade plastics.

-

Parts are generally stronger and more consistent due to uniform material flow.

6. Surface Finish and Accuracy

6.1 3D Printing Finish

-

Often visible layer lines.

-

May require post-processing like sanding, painting, or chemical smoothing for a polished look.

6.2 Injection Molding Finish

-

Produces smooth, uniform surfaces straight out of the mold.

-

Textures or patterns can be added to the mold surface for customization.

7. Sustainability and Waste

7.1 3D Printing’s Additive Advantage

-

Minimal waste — material is added only where needed.

-

Easy to produce on-demand, reducing excess inventory.

7.2 Injection Molding’s Trade-Off

-

Generates sprues and runners (excess plastic), but these can often be recycled.

-

Large-scale production can offset initial waste impact.

8. Choosing the Right Method

Exploring the Differences Between 3D Printing and Injection Molding

| Factor | 3D Printing | Injection Molding |

|---|---|---|

| Best For | Prototypes, small runs, complex designs | Mass production of simple parts |

| Speed to First Part | Hours | Weeks (mold making) |

| Cost at Low Volume | Low | High |

| Cost at High Volume | High | Low |

| Design Flexibility | Very high | Moderate |

| Strength & Consistency | Moderate | High |

9. Real-World Examples

-

3D Printing:

-

Aerospace companies print custom brackets and lightweight components for aircraft.

-

Dentists print custom aligners and surgical guides.

-

-

Injection Molding:

-

Toy manufacturers like LEGO use injection molding for precise, consistent bricks.

-

Automotive suppliers produce thousands of dashboard components per day.

-

Conclusion: Different Tools for Different Jobs

3D printing and injection molding are not direct competitors — they’re complementary technologies in the manufacturing toolbox.

-

3D printing shines when speed to prototype, design flexibility, and low-volume runs are priorities.

-

Injection molding dominates when scale, consistency, and low per-unit cost at high volumes matter.

Actionable Insight:

If you’re creating a new product, consider starting with 3D printing to refine your design. Once finalized and ready for large-scale production, transition to injection molding for efficiency and cost savings.

Future Outlook:

Hybrid approaches are emerging — using 3D printing to create injection molds themselves, cutting lead times and costs. As materials and technologies advance, the line between the two will continue to blur, giving designers and manufacturers more freedom than ever before