Blog

3D Printing Future in Comparison to AI and Robotics

3D Printing Future in Comparison to AI and Robotics

Introduction: A New Era of Technology Convergence, 3D Printing Future in Comparison to AI and Robotics

In the 21st century, technology is advancing at a pace that was once the stuff of science fiction. Three of the most disruptive innovations—3D printing, artificial intelligence (AI), and robotics—are rapidly transforming the way we design, build, and interact with the world. Each has evolved from niche applications into powerful forces shaping multiple industries. But their greatest potential lies not just in their individual capabilities, but in how they can work together to create smarter, more adaptable, and highly efficient systems.

In this article, we’ll explore where each technology stands today, what the future may hold, and how their paths intersect to redefine manufacturing, healthcare, space exploration, and beyond.

3D Printing: From Prototype Tool to Industrial Powerhouse

The Evolution of Additive Manufacturing ,3D Printing Future in Comparison to AI and Robotics

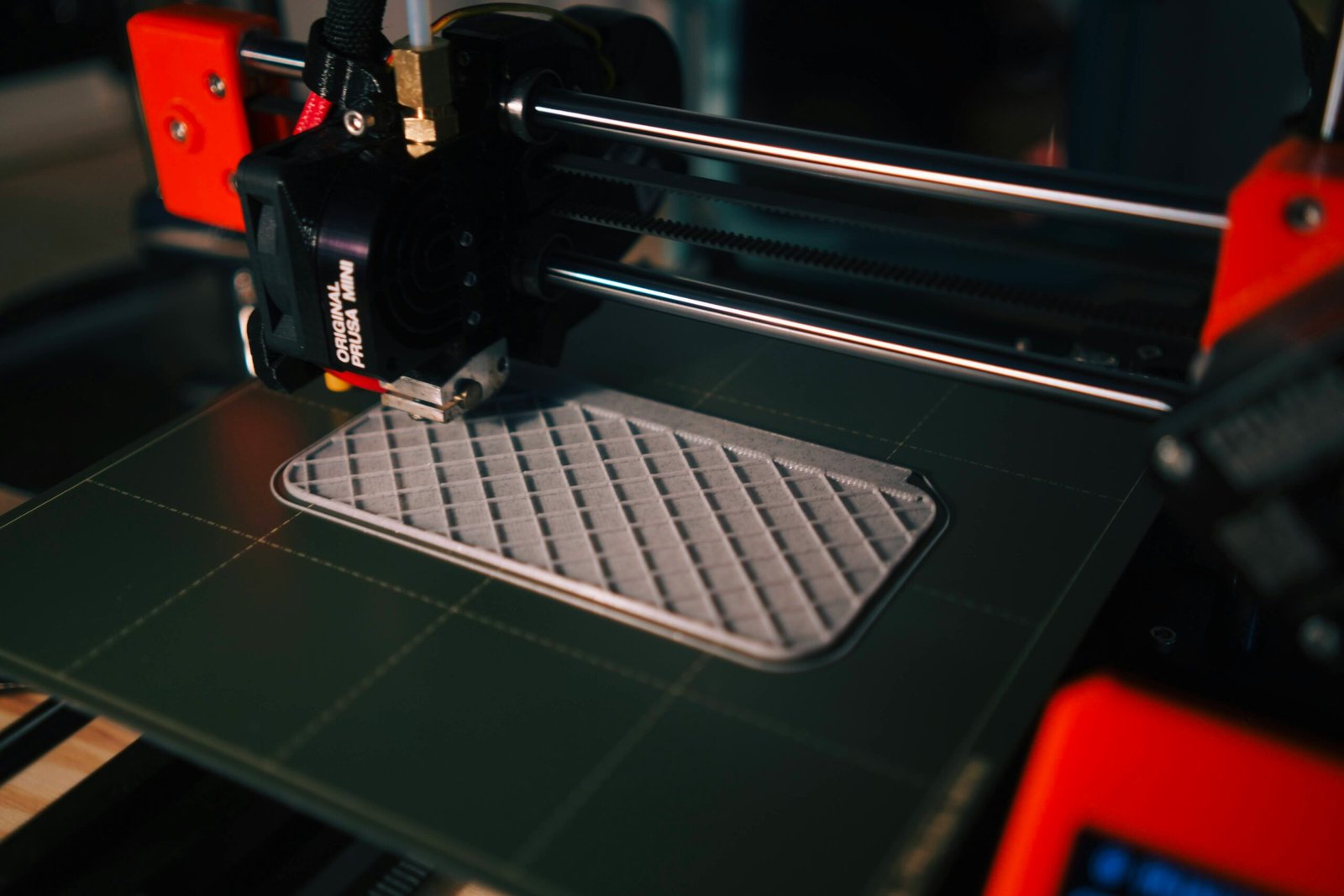

Initially viewed as a rapid prototyping method for engineers, 3D printing—also known as additive manufacturing—has moved far beyond simple models. Today, companies print aerospace-grade titanium parts, custom dental implants, fashion accessories, and even entire concrete houses.

One of its greatest strengths is design freedom. Unlike traditional manufacturing, which often involves cutting away from a solid block of material, 3D printing builds objects layer by layer, enabling intricate geometries impossible to create otherwise.

Advancements in Materials

Early 3D printing relied mostly on plastics, but the range of printable materials now includes:

-

Metals (e.g., aluminum, titanium, stainless steel) for aerospace and automotive parts.

-

Ceramics for electronics and high-temperature applications.

-

Bio-inks that can print living tissues and, in the future, entire organs.

-

Composite materials with carbon fiber for strength and durability.

This expansion means industries can create functional, end-use products rather than just prototypes.

The Future of 3D Printing

Looking forward, expect:

-

On-site printing in construction for faster, cheaper housing solutions.

-

Medical-grade printers in hospitals producing implants within hours.

-

Space-based manufacturing, where 3D printers on space stations can create tools and replacement parts without resupply missions from Earth.

Artificial Intelligence: The Brain of Modern Technology

From Rule-Based Systems to Deep Learning

Artificial intelligence began as a set of hard-coded instructions but has evolved into systems capable of learning from data. AI now powers:

-

Natural language processing (chatbots, translation tools).

-

Predictive analytics for business and logistics.

-

Computer vision for defect detection in manufacturing.

AI’s Role in Industry

In manufacturing, AI:

-

Optimizes production lines by predicting machine failures before they occur.

-

Improves quality control by identifying defects faster than humans.

-

Reduces energy consumption by dynamically adjusting processes.

The Next Stage of AI

We can expect AI to:

-

Make real-time, autonomous decisions in factories.

-

Drive fully automated supply chains that adjust instantly to demand changes.

-

Enable personalized product design by analyzing customer preferences and generating tailored blueprints for 3D printing.

Robotics: The Hands That Make Ideas Real

From Assembly Lines to Autonomous Systems

Robotics has evolved from simple, repetitive machines in assembly lines to complex, adaptive systems. Today’s robots:

-

Perform delicate surgeries with millimeter precision.

-

Sort and pack products in automated warehouses.

-

Explore hazardous environments like deep oceans or disaster zones.

The Push for Dexterity and Mobility

Future robotics will:

-

Feature AI-guided adaptability, allowing them to work in unpredictable environments.

-

Become more human-like in dexterity, handling fragile objects safely.

-

Operate collaboratively alongside humans (cobots), making production lines safer and more efficient.

Where They Intersect: 3D Printing + AI + Robotics

A Fully Integrated Smart Factory

Imagine a self-sufficient production system:

-

AI monitors market trends and predicts product demand.

-

3D printers create custom components on demand.

-

Robots assemble products, guided by AI for real-time adjustments.

-

Sensors and data feedback loops keep everything optimized without human intervention.

This integration means:

-

Mass customization becomes the norm.

-

Waste reduction through on-demand production.

-

Faster turnaround from concept to finished product.

Case Study: Aerospace Manufacturing

In aerospace, the integration is already happening:

-

AI designs lightweight components optimized for performance.

-

3D printing manufactures those designs in titanium.

-

Robots handle assembly and precision finishing.

The result? Lower costs, faster production, and stronger parts than traditional manufacturing could achieve.

Comparing Their Transformational Power

3D Printing Future in Comparison to AI and Robotics

| Feature | 3D Printing | AI | Robotics |

|---|---|---|---|

| Core Function | Creates physical objects layer-by-layer | Processes and learns from data | Physically manipulates the world |

| Key Strength | Design freedom & customization | Decision-making & optimization | Precision & repeatability |

| Limitation | Speed & material availability | Data quality & ethical concerns | Physical limitations & mobility |

| Future Role | On-demand production everywhere | Autonomous, intelligent control | Adaptive, collaborative work |